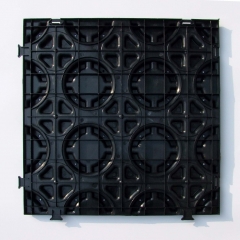

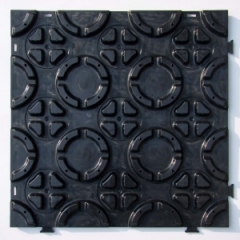

Black Radiant Floor Heating Hydronic Module

- WT4501

- 450*450*25mm

- Polypropylene

- Black

- 2000kg/m2

- 40℃ to 100℃

- Industrial, Commercial building heating/cooling systems, Agriculture, Animal husbandry, Forestry heating, Airports, schools, hospitals, Fishery

- 2.5kg/sqm

- 25pieces/carton

- 360CTN=1x40'GP

- 39259000

- Contact Now

Black Radiant Floor Heating Hydronic Module

Floor heating hydronic module mainly used under 60℃ water pour into the heating pipe that implementation of internal recycling as heat medium, setting the Hydronic systems under the floor to warm up the entire floor. It is a highly safety module to keep indoor warming; also it provide and reuse hot water in our life. With high compression strength and lightweight module design of Hydronic systems is makes installation easier, cheaper, safer than electric heating.

| Item No. | WT4501 |

| Color | Black |

| Dimension | 450*450*25mm |

| Weight | 2.5kg/m2 |

| Material | PP(Polypropylene) |

| Quantity of a Carton | 25 pieces |

| Coil Pipe Distance | 15cm |

| Suitable Pipe Caliber | 16cm |

| Water Distributor Module | 400*400*25m |

| Daily Capacity |

200sqm/Day |

| Toxicity | Nontoxic |

| Working life | More than 50 years |

FEATURES

1. Safety and useful

2. Recyclable

3. Corrosion resisting

4. Resist compression

5. Flame retardance

6. provide hot water

7. Made with Anti-pollution material

8. Easy to install and have buckle can fix the pipe directly

9. Do not release toxic gas over 100℃

10. Equal heating and keep the heat quantity lasting

11. High pressure strength

12. Good dielectric property and insulativity

13. Easy for air circulating

14. Low cost,saving building cost

15. Convenient maintenance

16. Reuse water

APPLICATION

1. Industry

2. Civil and Commercial building heating/refrigeration systems

3. Agriculture

4. Animal husbandry

5. Fishing Industry

6. Forestry

7. Airport

8. School

9. Hospital

10.Indoor

1. High pressure strength

2. Reduce labor cost,rapid and convenient construction

3. Good ability of heat storage

4. Partly soundproof effect

5. Energy conservation

6. Lightweight design,reduce the load of building

7. Heating rapidly:only need 10-20mins

8. Installation Flexibly

10. Working life more than 50 years

11. Have buckle can fix the pipe directly

PROJECT

Step1: Laying the reflectance coating or other insulation board

Step2: Laying the hydronic heating module upon the reflectance coating

Step3: Coiling pipe on hydronic heating module

Step4: Backfill concrete or paving ground decoration directly

PreviousEnvironmental Grid Module for Radiant Floor Heating

NextHydronic Radiant PP Floor Heating System